- PID

- 3743823

Solid Lubricant Bearings

These are specially designed bearings that can be used in high-temperature environments or areas with heavy dust and contamination.

- Certification

-

- Award

-

- Shipping

-

- Payment

-

140+ Global Payments, trusted and secure payment provided by PayVerse.

Learn More

- Quantity

- MOQ : 1 Pieces

Product Summary

• Brand name: Jung Hyun Compound Corp.

• Type: bearings

• Application: Steel Industry, Ceramic Industry, Food Industry

Glass Industry, Aluminum Industry, Battery materials industry(Anode industry/Cathode industry)

• Material: Carbon Graphite based

• Size/Dimension: variable

Detailed Description

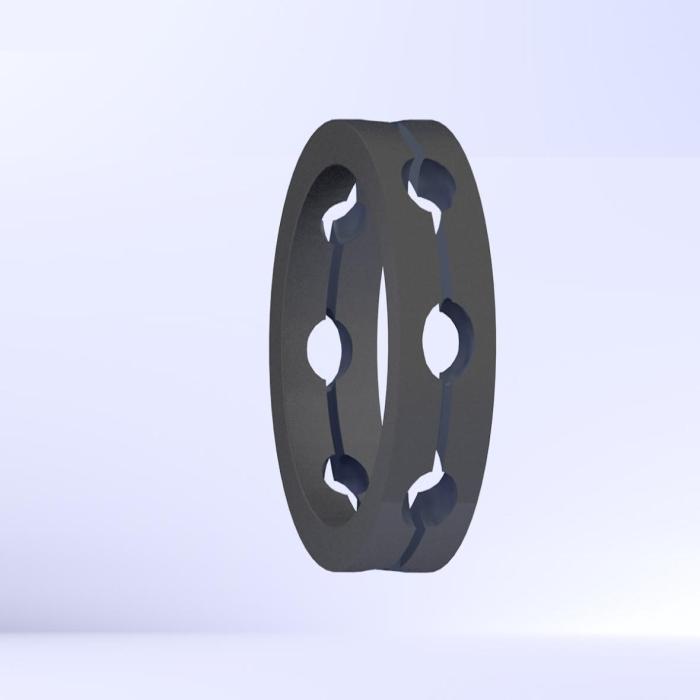

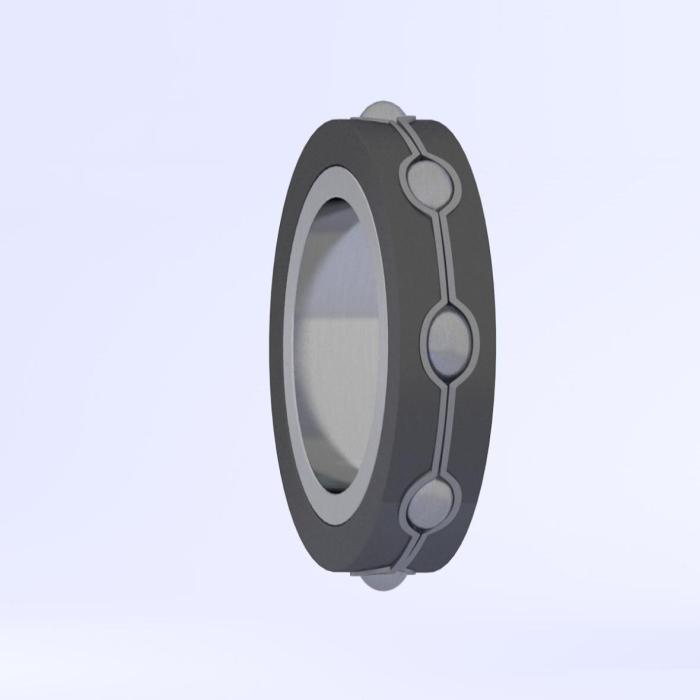

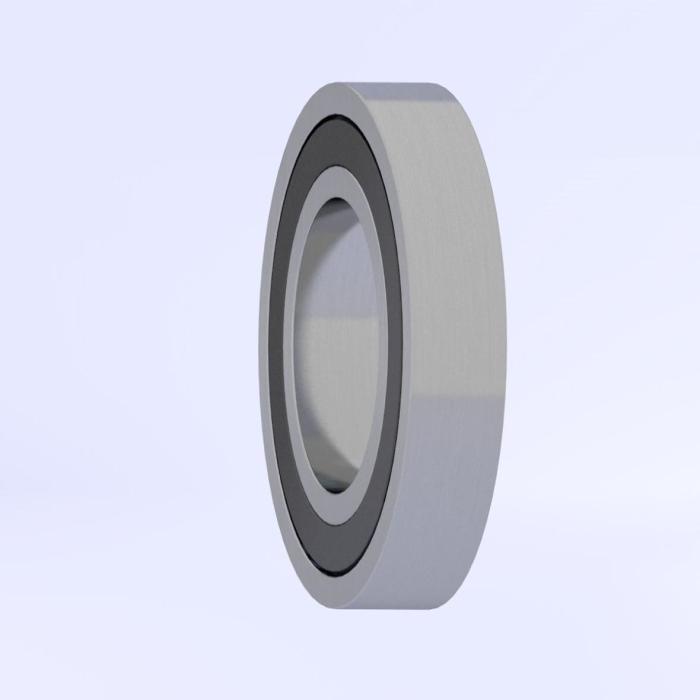

Compound Bearing is a type of solid lubricant bearing that ensures long-term use without the need for re-lubrication. This is achieved by filling and solidifying a graphite-based compound between the inner and outer rings, which provides continuous lubrication during rotation.

A key advantage is its ability to overcome the limitations of conventional grease, which degrades rapidly at high temperatures. Our Compound Bearing guarantees stable operation in a wide temperature range, from -60°C to 350°C. Furthermore, it extends the bearing's lifespan and maintains performance even in challenging conditions. The fine-particle crushing and sealing effects of the compound molecules protect against the ingress of foreign particles in high-dust environments and resist exposure to chemical substances.

This product is gaining attention in various industries, including steel, glass, ceramics, food, aluminum, and automotive painting lines, as well as in vacuum-based applications and the manufacturing of secondary battery materials like anodes and cathodes. It demonstrates outstanding performance in situations requiring long-term stability, such as high-temperature, high-dust environments or settings where re-lubrication and maintenance are difficult.

Our Compound Bearings can be adapted to any application, regardless of type, size, material, or quantity. We manufacture a wide variety of bearing types, including:

-

Deep Groove Ball Bearings

-

Miniature Ball Bearings

-

Angular Contact Ball Bearings

-

Self-Aligning Ball Bearings

-

Spherical Roller Bearings

-

Cylindrical Roller Bearings

-

Tapered Roller Bearings

-

Self-Aligning Roller Bearings

-

Unit Bearings (UC, UK, SB, etc.)

Instead of using the graphite segment method, we employ a more robust technique by filling the compound directly into the bearing's existing retainer.