- PID

- 3323087

Insulation and Heat Shield Paint

- Certification

-

- Award

-

- Shipping

-

- Lead Time3 ~ 7days

- Products Shipped From Seoul

- Payment

-

140+ Global Payments, trusted and secure payment provided by PayVerse.

Learn More

- Quantity

- MOQ : 200 Kilograms

Detailed Description

Product Name: Eco-friendly water-soluble stepped Insulation and Heat Shield paint

1. Scope and content of technology

1) Applicable target: general buildings, industrial buildings

2) Green New Deal: Mandatory Zero Energy Building

-With the establishment of Article 12, Paragraph 3 of the Enforcement Decree of the Green Building Creation Support Act,

Zero-energy buildings are mandatory for new or extended buildings from 2020

-This product is an essential material required for the energy-saving zero-house housing introduction policy.

-If the zero-energy building certification obligation system goes as planned, the GHG reduction roadmap

exceeds the new building reduction target (5.4 million tons) in 2030.

It is expected to reduce GHG emissions by 5.42 million tons.

3) Contributing to building energy efficiency improvement by using it on the exterior wall of factory industrial

construction materials and the interior and exterior walls of building panels, especially in summer

Reduction and reduction of outflow of heating energy in winter

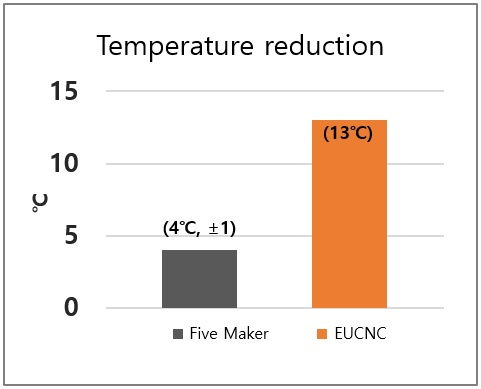

2. Advantages of heat insulating paint

1) Water-soluble paints use water instead of solvents or monomers when adjusting viscosity,

so they have little toxicity, no smell, and no skin damage.

2) It is also possible by general painting methods

3) As it uses less monomer, it has low shrinkage and excellent adhesion to plastic-like materials.

4) Since the cured coating does not contain unreacted monomer, it has a high curing rate and forms a flexible coating.

5) Curing at low temperature

6) As a water-soluble paint, it is not harmful to the human body and is an eco-friendly product free of VOCs, VACs, heavy metals, etc.

3. Diversification of uses

1) Step heat effect

① Interior and exterior walls of apartments, houses, factories, and livestock houses (new/remodeled)

② Apartments, houses, factories, barn ceilings, roofs and rooftops (new/remodeled)

③ Outdoor storage tank, boiler, high-temperature industrial machinery and piping, steam piping insulation

-Prevents human injury and saves energy when painting on high-temperature industrial facilities below 400℃

④ Container house and office interior and exterior walls, ceiling, roof

⑤ Inner walls and ceilings of freezing and refrigerating vehicles

⑥ Freezing, refrigeration, low temperature, thermal storage

2) Environment improvement

① Where condensation and mold prevention are required

-Veranda, utility room, basement stairs, basement wall and ceiling

② Nursery, educational institution, interior and exterior walls, ceiling, roof

-Improvement of step heat and indoor air quality

③ Where noise reduction is required (around roads, around airports and air routes, around factories)

-Noise reduction 8~10 dB

3) Processability

Depending on the use of the interior and exterior of the building, it is possible to produce and apply

as interior insulation, exterior insulation, exterior stage insulation finishing, interior and exterior panels.