- PID

- 3041145

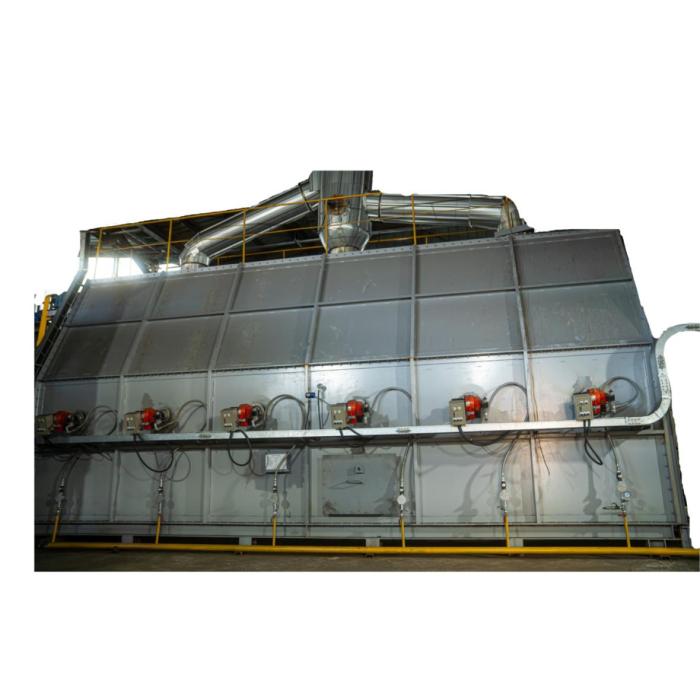

38.4t/d Eco Friendly Continuous Pyrolisis Facility and Plant for Waste Vinyl and Waste Synthetic Resins

- Certification

-

- Award

-

- Shipping

-

- Type of Freight Proceed after consultation

- Modes of Transport Proceed after consultation

- Payment

-

140+ Global Payments, trusted and secure payment provided by PayVerse.

Learn More

- Quantity

- MOQ : 1 Plants

Detailed Description

Eco-friendly continuous pyrolysis technology is a waste synthetic resin The gas is indirectly heated to change its properties, transforming it into synthetic gas, and then pyrolytic oil, Pyrolysis gas, Char It is a technology that reproduces with available resources.

Our technology reduces the input amount of waste synthetic resins by approximately 90% is produced as a resource.

Currently produced pyrolysis oil is sold as a recycled raw material.

Medicine of produced pyrolysis gas 15% is used as its own fuel, and the remaining gas is stored and incinerated.

Surplus gas has a successful history of hydrogen reforming, and based on this, it can be used for hydrogen production business or gas turbine power generation..

Powder form Char, which is a carbide of is about 3500~5000kcal This is a carbon compound with and is being prepared to be used as a carbon fiber or fuel.