- PID

- 3100020

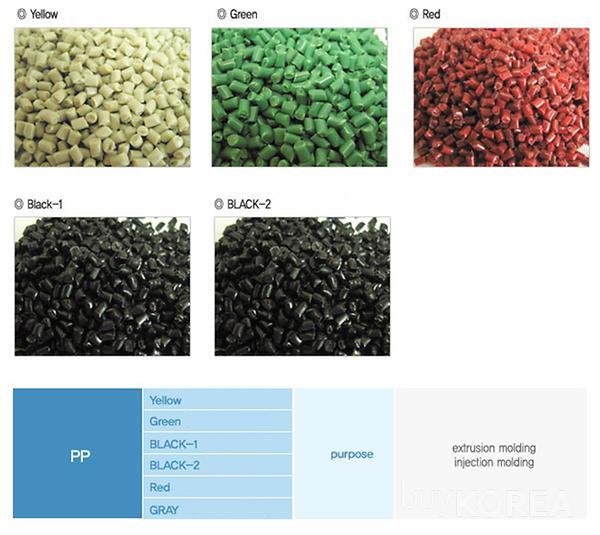

PP pellet, Plastic Resin PP, PolyPropylene

- Award

-

- Shipping

-

- Payment

-

140+ Global Payments, trusted and secure payment provided by PayVerse.

Learn More

Detailed Description

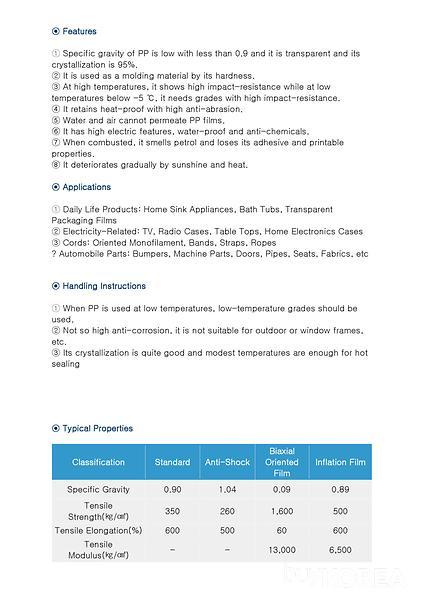

⊙ Features

① Specific gravity of PP is low with less than 0.9 and it is transparent and its crystallization is 95%.

② It is used as a molding material by its hardness.

③ At high temperatures, it shows high impact-resistance while at low temperatures below -5 ℃, it needs grades with high impact-resistance.

④ It retains heat-proof with high anti-abrasion.

⑤ Water and air cannot permeate PP films.

⑥ It has high electric features, water-proof and anti-chemicals.

⑦ When combusted, it smells petrol and loses its adhesive and printable properties.

⑧ It deteriorates gradually by sunshine and heat.

⊙ Applications

① Daily Life Products: Home Sink Appliances, Bath Tubs, Transparent Packaging Films

② Electricity-Related: TV, Radio Cases, Table Tops, Home Electronics Cases

③ Cords: Oriented Monofilament, Bands, Straps, Ropes

? Automobile Parts: Bumpers, Machine Parts, Doors, Pipes, Seats, Fabrics, etc

⊙ Handling Instructions

① When PP is used at low temperatures, low-temperature grades should be used.

② Not so high anti-corrosion, it is not suitable for outdoor or window frames, etc.

③ Its crystallization is quite good and modest temperatures are enough for hot sealing

⊙ Typical Properties

|

Classification |

Standard |

Anti-Shock |

Biaxial Oriented Film |

Inflation Film |

|

Specific Gravity |

0.90 |

1.04 |

0.09 |

0.89 |

|

Tensile Strength(㎏/㎠) |

350 |

260 |

1,600 |

500 |

|

Tensile Elongation(%) |

600 |

500 |

60 |

600 |

|

Tensile Modulus(㎏/㎠) |

- |

- |

13,000 |

6,500 |

|

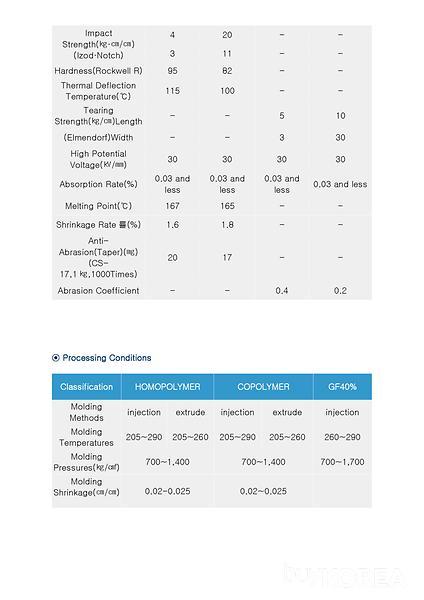

Impact Strength(㎏·㎝/㎝) |

4 |

20 |

- |

- |

|

3 |

11 |

- |

- |

|

|

Hardness(Rockwell R) |

95 |

82 |

- |

- |

|

Thermal Deflection Temperature(℃) |

115 |

100 |

- |

- |

|

Tearing Strength(㎏/㎝)Length |

- |

- |

5 |

10 |

|

(Elmendorf)Width |

- |

- |

3 |

30 |

|

High Potential Voltage(㎸/㎜) |

30 |

30 |

30 |

30 |

|

Absorption Rate(%) |

0.03 and less |

0.03 and less |

0.03 and less |

0.03 and less |

|

Melting Point(℃) |

167 |

165 |

- |

- |

|

Shrinkage Rate률(%) |

1.6 |

1.8 |

- |

- |

|

Anti-Abrasion(Taper)(㎎) |

20 |

17 |

- |

- |

|

Abrasion Coefficient |

- |

- |

0.4 |

0.2 |

⊙ Processing Conditions

|

Classification |

HOMOPOLYMER |

COPOLYMER |

GF40% |

||

|

Molding Methods |

injection |

extrude |

injection |

extrude |

injection |

|

Molding Temperatures |

205~290 |

205~260 |

205~290 |

205~260 |

260~290 |

|

Molding Pressures(㎏/㎠) |

700~1,400 |

700~1,400 |

700~1,700 |

||

|

Molding Shrinkage(㎝/㎝) |

0.02-0.025 |

0.02~0.025 |

|||