- PID

- 3036753

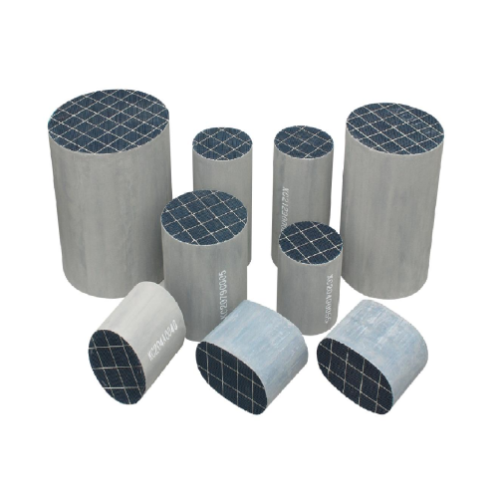

SiC DPF

- Certification

-

- Award

-

- Shipping

-

- Lead Time45 ~ 70days

- Modes of Transport CIF,EXW,FOB

- Payment

-

140+ Global Payments, trusted and secure payment provided by PayVerse.

Learn More

- Quantity

- MOQ : 100 Pieces

Detailed Description

IB MATERIALS has know-how and technology for DPF/Catalysts pass regeneration system,

complex regeneration since it supplied products to the Korean Government in the retrofit project for a decade.

IB MATERIALS is located in Mokpo, South Jeolla Province. Our production line contains state-of-the-art technology

which enable us to produce high quality SIC DPF’s with customized shapes and sizes within a short period.

All IB MATERIALS DPF’s have low back pressure, high durability, and an oxide layer

that makes the filter extremely susceptible to catalytic coatings, including precious metals.

To ensure these good properties we have quality control of all DPF’s and constant development of all our products to ensure the best quality for our customers.

Visit our website https://www.ibmaterials.co.kr for more information about our products, process, and company.

IB MATERIALS is the only domestic company that is skilled in Ceramics and Catalysts.

Also, have excellent capability of producing a SiC DPF. Our product is known for high-performance

(porosity 60%, PM collection 96% over) Through many types of SiC DPF (100, 200, 300 CPSI and leading to several types of 1 ~ 30Liter),

it can apply to various applications and meet with a strict environmental regulation such as EURO V, VI

Production from IB MATERIALS Co. Ltd is a set of rules and regulations that must be adhered in an environmental law.

And the reduction of PM-NOx can be done by using our products with high coating capacity.

Silicon Carbide Based DPF is widely applied in the areas that use diesel engines such as automobiles

and generators with high pores and PM removal rates.

We've made develop the high porosity DPF to meet the demand of the market.

The developed product has three superior performances compared to the normal product.

First, we're able to observe dramatic improvement in porosity.

A porosity at DPF is an important feature due to allowing itself to seize PM.

The amount of capturing PM is decided by the size of DPF.

Therefore, 32% improvement of backpressure is an important development to provide new value

to a business company like the manufacturer of the marine vessel.

To sum it up, IB MATERIALS has enormously increased the amount of capturing PM(12g/L→14g/L)

Second, the physical characteristic has been improved in both thermal characteristics enhancement and light weighting decreased by 15%.